The pallet racking system is the esstential storage equipment of almost every modern warehouse. It is the critical equipment used to maximize storage space and streamline warehouse management. But there is one question that keeps warehouse managers up at night: "Is it safe? How much weight can this rack actually hold?"

With over 20 years of racking project experience at HEDA SHELVES, we have seen it all—from light retail storage to massive industrial distribution centers. Generally speaking, a standard industrial pallet rack system is designed with a load capacity of around 3-5 tons per layer, depending on the configuration. However, guessing is not an option when safety is on the line.

In this article, we will provide a thorough understanding of pallet racking weight capacity, offer solutions for accurate calculations, and share a real-world case study from our portfolio.

Key Takeaways

Understanding Pallet Rack Weight Capacity

When we talk about "capacity," we are actually talking about two different ratings that work together. As experts, we encourage you to distinguish between them:

Beam Capacity (Per Layer): This is the maximum weight a pair of beams can hold. For example, if you have two pallets weighing 1500kg each sitting on one level, your beam capacity must be at least 3000kg.

Upright Frame Capacity (Total Bay): This is the total weight the vertical frames can support. This includes the weight of all the layers combined.

Expert Note: Most rack damage case failures happen not because the steel wasn't strong enough, but because the weight was unevenly distributed. Always ensure your loads are uniformly distributed (UDL).

Factors That Determine Pallet Rack Capacity

Why can one rack hold 1000kg and another hold 5000kg? It comes down to engineering.

Beam Profile and Plate Thickness

As the horizontal components directly bearing loads, common beam types include box beams and ladder beams. Beam thickness and profile cross-section determine load-bearing capacity. Deeper cross-sections and thicker, stronger beams enhance load capacity and durability.

At HEDA, we focus on two aspects:

When selecting a shelving system, prioritize beam specifications, as these parameters directly determine the load-bearing capacity of pallet rack beams.

The upright frames take the total vertical load of the entire bay and transfer it to the floor.

With Our 20 years experience in racking system design, the beam span limited in 3m can balance the pallet postion and load capacity. As the span (the distance between the two uprights) increases, the capacity of the beam decreases.

For example, a 120mm beam might hold 3,000kg at a 2,300mm length, but that same beam may only safely hold 2,000kg if stretched to a 3,300mm length.

Common Pallet Racking Beams Maximum Load Capacity (Basic on HEDA SHELVES Standard)

Single Beam

| No. | Type | Section Size (H×B, mm) | 1000 | 1500 | 2000 | 2300 | 2500 | 2700 | 3000 | 3300 | 3500 | 3800 | 4000 | Unfolded Width (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Single Beam | 80×45×1.5 | 2918 | 1946 | 1459 | 1173 | 993 | 851 | 690 | 570 | 507 | 430 | 388 | 290 |

| 2 | Single Beam | 100×45×1.5 | 4160 | 2773 | 2080 | 1809 | 1560 | 1337 | 1083 | 895 | 796 | 675 | 609 | 330 |

| 3 | Single Beam | 120×45×1.5 | 6454 | 4303 | 3227 | 2825 | 2391 | 2050 | 1661 | 1372 | 1220 | 1035 | 934 | 370 |

| 4 | Single Beam | 140×45×1.5 | 7959 | 5306 | 3980 | 3461 | 3184 | 2950 | 2389 | 1975 | 1755 | 1489 | 1344 | 410 |

| 5 | Single Beam | 160×45×1.5 | 9566 | 6377 | 4783 | 4159 | 3826 | 3543 | 3189 | 2712 | 2411 | 2045 | 1846 | 450 |

| No. | Type | Section Size (H×B, mm) | 1000 | 1500 | 2000 | 2300 | 2500 | 2700 | 3000 | 3300 | 3500 | 3800 | 4000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Reinforced Double Beam | 80+80 | 10355 | 6903 | 5178 | 4502 | 4142 | 3835 | 3452 | 2921 | 2597 | 2203 | 1988 |

| 2 | Reinforced Double Beam | 100+80 | 12268 | 8179 | 6134 | 5334 | 4907 | 4544 | 4089 | 2718 | 3461 | 2936 | 2650 |

| 3 | Reinforced Double Beam | 100+100 | 14143 | 9429 | 7071 | 6149 | 5657 | 5238 | 4714 | 4286 | 4041 | 3722 | 3394 |

| 4 | Reinforced Double Beam | 120+100 | 16263 | 10842 | 8131 | 7071 | 6505 | 6023 | 5421 | 4928 | 4647 | 4280 | 4066 |

| 5 | Reinforced Double Beam | 120+120 | 18366 | 12244 | 9183 | 7985 | 7347 | 6802 | 6122 | 5566 | 5248 | 4833 | 4592 |

| 6 | Reinforced Double Beam | 140+120 | 20695 | 13797 | 10348 | 8998 | 8278 | 7665 | 6898 | 6271 | 5913 | 5446 | 5174 |

| 7 | Reinforced Double Beam | 140+140 | 23024 | 15349 | 11512 | 10010 | 9210 | 8527 | 7675 | 6977 | 6578 | 6059 | 5756 |

| 8 | Reinforced Double Beam | 160+140 | 25563 | 17042 | 12782 | 11114 | 10225 | 9468 | 8521 | 7746 | 7304 | 6727 | 6391 |

| 9 | Reinforced Double Beam | 160+160 | 28114 | 18743 | 14057 | 12224 | 11246 | 10413 | 9371 | 8520 | 8033 | 7399 | 7029 |

| No. | Type | Section Size (H×B, mm) | 1000 | 1500 | 2000 | 2300 | 2500 | 2700 | 3000 | 3300 | 3500 | 3800 | 4000 | Unfolded Width (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Square Beam | 80×45×1.5 | 1829 | 1219 | 914 | 735 | 622 | 533 | 432 | 357 | 317 | 269 | 243 | 250 |

| 2 | Square Beam | 100×45×1.5 | 2688 | 1792 | 1344 | 1169 | 1008 | 864 | 700 | 578 | 514 | 436 | 394 | 290 |

| 3 | Square Beam | 120×45×1.5 | 4298 | 2866 | 2149 | 1869 | 1593 | 1365 | 1106 | 914 | 813 | 689 | 622 | 330 |

| 4 | Square Beam | 140×45×1.5 | 4521 | 3014 | 2260 | 1965 | 1808 | 1675 | 1357 | 1121 | 997 | 846 | 763 | 370 |

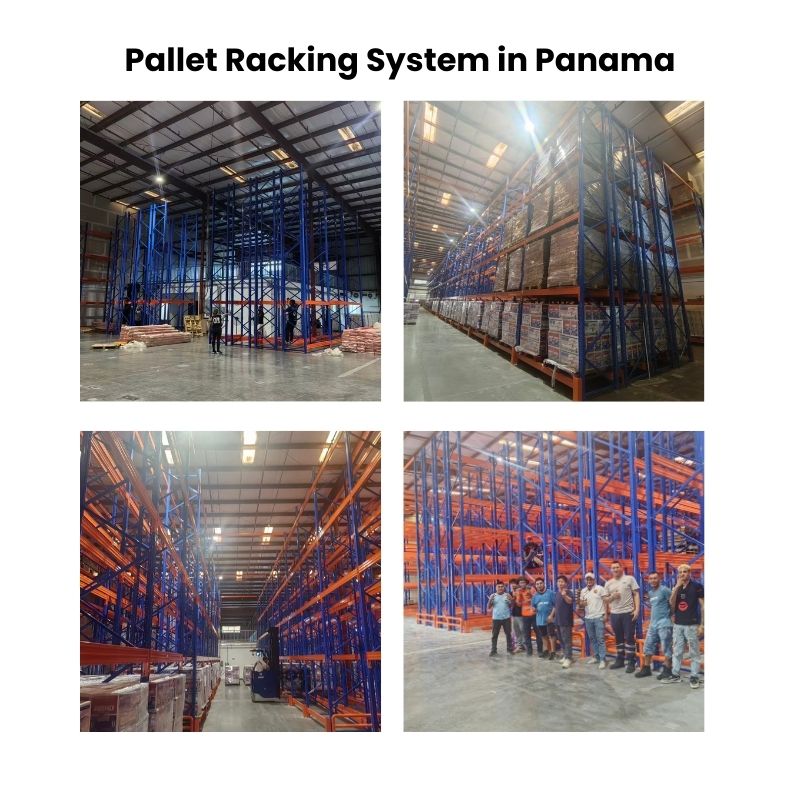

Client Challenge: A large logistics center in Panama needed to store heavy industrial machinery parts. They required a system that could handle extreme weight loads while remaining stable in a seismically active region.

HEDA Solution: We engineered a custom Heavy Duty Selective Racking System.

Specs: We utilized our 160mm Integrated Beams to achieve a reliable load capacity of 3.5 tons per layer at a 2700mm beam length.

Safety: We installed column guards and frame protectors to prevent forklift damage.

Result: The client maximized their vertical space safely, holding heavy machinery parts that standard racks couldn't support.

If you’re looking for pallet racking in your warehouse, HEDA SHELVES has got you covered!

From pallet racking design to on-site installation support, we offer OEM/ODM shelving and racking solutions available to suit your business needs. As shown in our data above, we engineer racks for everything from light storage to super-heavy industrial loads.

Got any questions about our products? Contact our friendly team today who will be happy to assist you with your enquiry!

Q: How do I calculate the weight of my pallets?

A: Weigh your heaviest pallet load (product + pallet weight). Multiply this by the number of pallets per beam level. Your beam capacity must exceed this total number.

Q: What happens if I overload a rack?

A: Overloading causes beam deflection (bowing). If the beam bows more than its limit (usually 1/180th of the length), it is structurally compromised and risks collapsing.

Q: Can HEDA Shelves customize the beam length?

A: Yes. While 2300mm, 2500mm, and 2700mm are standard, we can manufacture beams to any specific length (e.g., 1000mm to 4000mm) as shown in our technical capabilities.

Hi! Click one of our members below to chat on